Lawmakers Grill Vaccine Factory Executives About Manufacturing Mistakes

As Emergent BioSolution's Baltimore factory was throwing away unfinished COVID-19 vaccine doses and struggling to pass muster with the Food and Drug Administration, the company awarded at least $3 million in bonuses to a handful of executives, according to documents released by a congressional subcommittee Wednesday.

The House Select Subcommittee on the Coronavirus Crisis grilled executives from Emergent, which was awarded a $628 million contract with the federal government to boost COVID-19 vaccine manufacturing capacity. The subcommittee released a trove of documents ahead of the hearing that revealed more details about the history of Emergent's manufacturing difficulties, as well as executives' 2020 bonus compensation.

The company received $27 million a month from the federal government, regardless of whether it produced vaccine, the documents show.

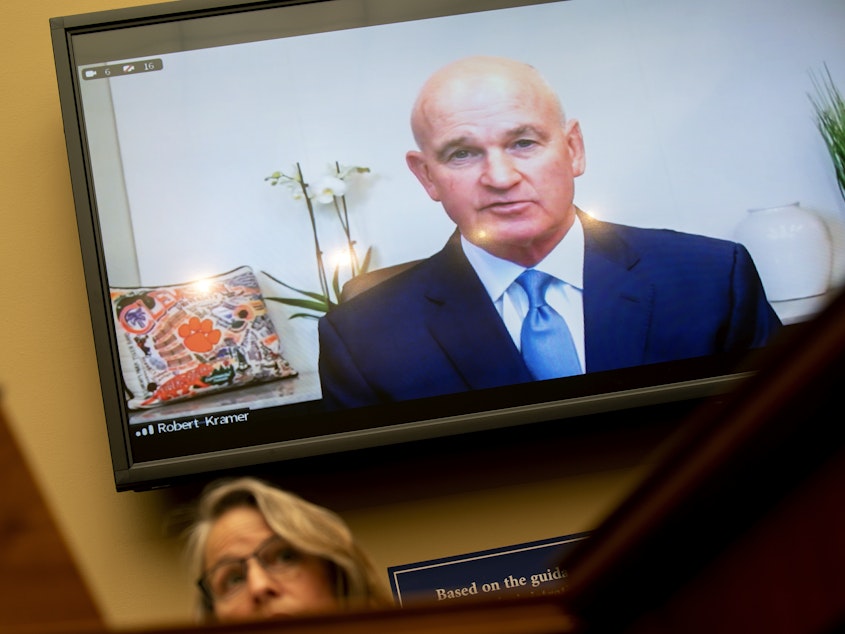

"Out of $628 million committed dollars in which $271 million have been sent, have we been able to get one vaccine? Yes or no?," Rep. Carolyn Maloney, a New York Democrat, asked the executives.

"None of the vaccine that we've manufactured has been made available to the U.S.," Emergent CEO Robert Kramer answered.

Sponsored

Kramer's 2020 bonus was worth more than $1.2 million, according to newly released minutes from a meeting of Emergent's compensation committee on Feb. 9. Several other executives each received hundreds of thousands of dollars in bonuses.

"I am really posing to my colleagues, we should at least write procurement laws that if you are not producing the product, you shouldn't be paid," Maloney said later in the hearing. "You certainly shouldn't get a bonus. And you should not give a contract to a company that does not have a track record of completing the task."

Emergent was thrust into the spotlight in March with a revelation that it mixed up Johnson & Johnson vaccine ingredients with components of AstraZeneca's COVID-19 vaccine, forcing it to throw away unfinished doses earlier this year.

Although the FDA authorized Johnson & Johnson's vaccine for emergency use in February, Emergent has not been OKed to formally join its supply chain. As a result, none of what Emergent's Baltimore factory has produced has made it to vaccines bound for the American public. Meanwhile, the Johnson & Johnson vaccine supply has been low.

Although Emergent has manufactured uncontaminated vaccine batches, the FDA needs to give its blessing for the product to be put in vials and distributed.

Sponsored

"There are a significant number of doses that we've manufactured," Kramer told Rep. Steve Scalise, R-La., noting that Emergent only makes bulk drug substance, not finished doses ready for shipment and injection. "There are probably over 100 million doses of the J&J vaccine that we've manufactured that are now being evaluated by the FDA for potential release."

In June 2020, the same month Emergent was awarded its Operation Warp Speed contract, the federal government identified "significant risks" at Emergent's Baltimore factory concerning staffing and compliance.

"The staffing plans presented seem inadequate to the level of concurrent activities required for full scale production of three programs," a newly released Operation Warp Speed document reads. "In addition, recent FDA and customer audits has [sic] highlighted the need for extensive training of personnel and strengthening of the quality function."

Ten months later, the FDA found that staff training was still a problem.

An FDA inspection following Emergent's Johnson & Johnson mixup revealed nine problems, including that "employees were not trained in the particular operation that they performed and/or in [current Good Manufacturing Practices] related to their job function." Inspectors also determined Emergent didn't properly investigate how the cross-contamination happened, and concluded that "there is no assurance that other batches have not been subject to cross-contamination."

Sponsored

Pressed during the hearing about how it happened, Kramer wasn't entirely sure.

"The cross contamination occurred as a result of material that was leaving the AstraZeneca suite following a production cycle and production run," he said. "And as it was being exited out of our facility, it came in the general vicinity of some media that was being prepared for the initiation of a J&J run. So we don't know exactly how the virus of the AstraZeneca product was transferred into the media. But somehow it was." [Copyright 2021 NPR]